EXCAL is a project that arises from the need to calculate TEMA type “Shell and tube” exchangers, optimized in mass and performance, using finite elements and CFD calculation technology for INGENIERÍA Y MONTAJE RÍAS BAJAS, S.A.

The traditional process of calculating a heat exchanger according to TEMA is a laborious and repetitive process, which is performed by finite element analysis of 3D CAD models of heat exchangers. To reach the optimum geometry, a large number of finite element analyses and consecutive modifications of the 3D models are required to find a compliant heat exchanger at a moderate price, which makes the design of a compliant design a slow process.

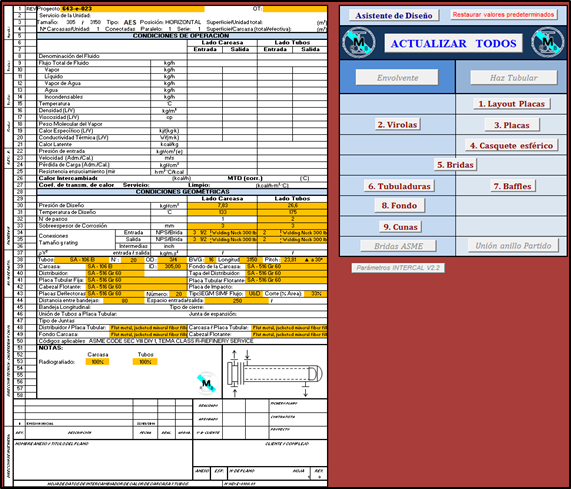

This problem was addressed by the realization of a design and dimensioning software for shell and tube heat exchangers (INTERCAL), which checks the compliance with the TEMA standard for the indicated conditions of temperatures, pressures, fluids, ferrule dimensions, wall thicknesses… Additionally, once the appropriate geometry is found, it performs the 3D CAD fully automatically in SolidWorks software with which to perform a FEM analysis and check the results.

By avoiding consecutive analysis and modification of the geometry, a time reduction of 30%, an increase in the company’s productivity, an improvement in the energy efficiency of the heat exchangers and the optimization of the material used are achieved.